ผลิตภัณฑ์ที่ครอบคลุมทุกอุตสาหกรรม

QSK 60 Containerized

เครื่องกำเนิดไฟฟ้าสำหรับธุรกิจ Data Center และ

อุตสาหกรรมอื่นๆ ที่เจ๋งกว่าใคร

- ระบบกำเนิดไฟฟ้าทั้งหมดมาพร้อมใช้ในตู้คอนเทนเนอร์ขนาดมาตรฐาน เรียกว่าวางปุ๊บ ใช้งานได้ปั๊บ*

- จัด วาง เรียง ซ้อน (Stack) ได้ตามข้อจำกัดของพื้นที่

เมื่อโลกขับเคลื่อนด้วย Data ให้ Data Center ขับเคลื่อนด้วยเรา

เรานำเสนอวิธีการทำงานที่เหมาะสมและดีที่สุดสำหรับคุณ

เรานำเสนอโซลูชั่นครบวงจรสำหรับทุกความต้องการ ตั้งแต่เครื่องยนต์ดีเซลสำหรับทุกงาน เครื่องกำเนิดไฟฟ้าครอบคลุมธุรกิจที่หลากหลาย ไปจนถึงบริการหลังการขาย อาทิ ชิ้นส่วน อะไหล่ วัสดุสิ้นเปลือง การซ่อมบำรุง ทำ PM หรือการยกเครื่องประจำปี ศูนย์บริการ วิศวกร และช่างเทคนิคของเราได้รับการรับรองมาตรฐานระดับสากลโดย Cummins Inc เรามีทีมขายให้การสนับสนุนทั่วประเทศรวมถึงลาวและกัมพูชา เราเป็นพันธมิตรด้านด้านพลังงานที่ธุรกิจของคุณสามารถไว้วางใจ

เครื่องยนต์ดีเซล

เครื่องยนต์ดีเซลสำหรับทุกความต้องการ

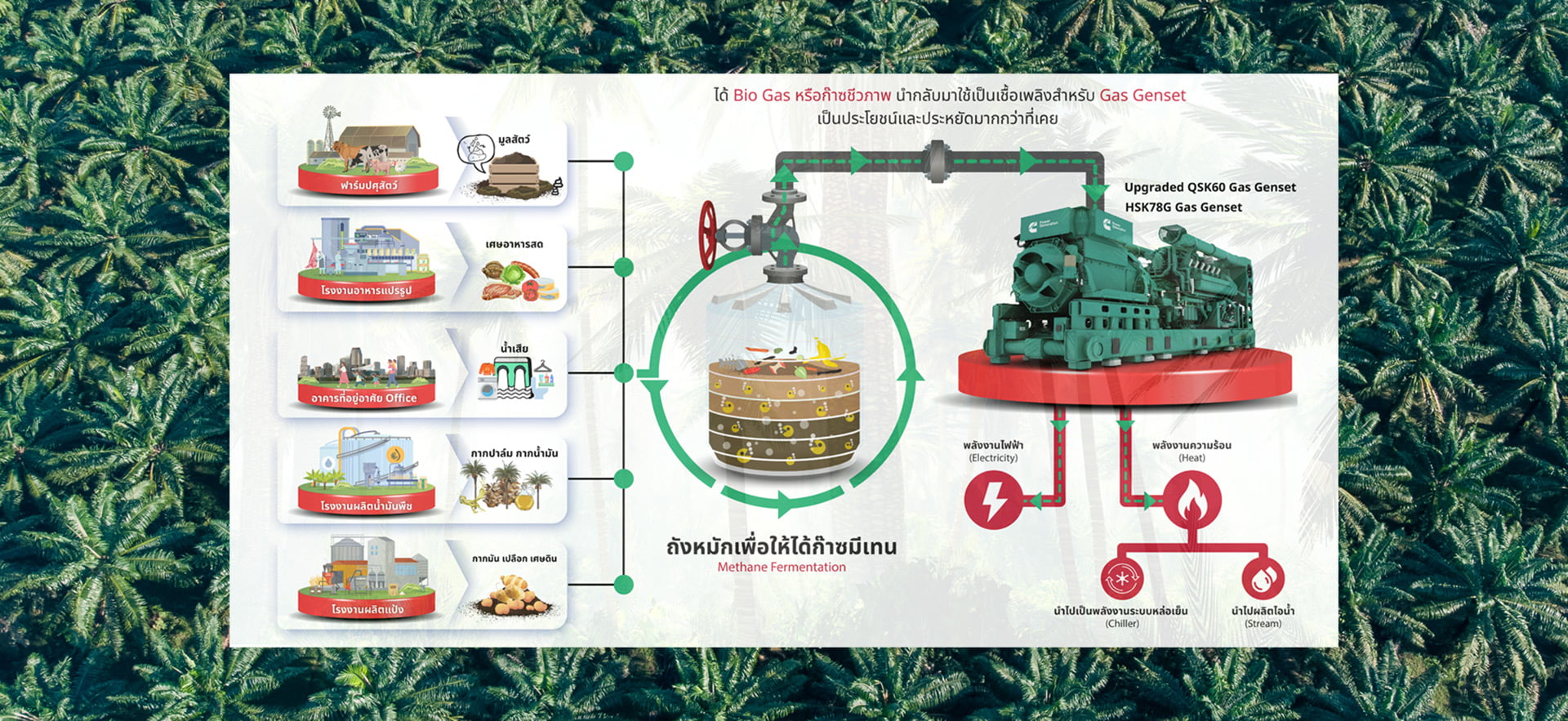

เครื่องยนต์ดีเซล เครื่องยนต์ก๊าซธรรมชาติ และเครื่องยนต์พลังงานทางเลือกของเราได้รับการออกแบบโดยผู้เชี่ยวชาญเพื่อให้ได้สมรรถนะที่เหนือกว่า และเหมาะสมกับ Application ที่แตกต่างกัน เพื่อตอบสนองทุกความต้องการของคุณอย่างสูงสุด

เครื่องกำเนิดไฟฟ้าและระบบกำเนิดพลังงาน

พร้อมเสมอ เพื่อการทำงานอย่างต่อเนื่อง

ตั้งแต่เครื่องกำเนิดไฟฟ้าสแตนด์บายที่มีความสำคัญยิ่งต่อภารกิจช่วยชีวิต ไปจนถึงการสำรองพลังงานไฟฟ้าสำหรับบ้าน อาคารสูง สายการผลิต หรือธุรกิจทั้งหมด เรามีโซลูชั่นเครื่องกำเนิดไฟฟ้าที่ครอบคลุมทุกความท้าทายและข้อจำกัดของคุณ

ชิ้นส่วนและอะไหล่แท้คัมมิ่นส์

อะไหล่แท้นำมาซึ่งความทนทาน ความคุ้มค่า และความสบายใจ

อะไหล่แท้ของคัมมิ่นส์ผลิตขึ้นตามหลักวิศวกรรมและข้อกำหนดเฉพาะสำหรับผลิตภัณฑ์นั้น ด้วยวัสดุและขั้นตอนที่การผลิตที่ได้รับการควบคุมโดยผู้เชี่ยวชาญของเรา นี่คือเหตุผลที่ว่าทำไมจึงต้องอะไหล่แท้เท่านั้น

ศูนย์ซ่อมมาตรฐานคัมมิ่นส์แห่งเดียวในประเทศไทย

ศูนย์บริการซ่อมและช่างเทคนิคที่ผ่านมาตรฐานและการรับรองโดย Cummins Inc แต่เพียงผู้เดียวในประเทศไทย

เราให้บริการงานซ่อมที่เหมาะสมเฉพาะกับความต้องการของคุณ ด้วยการตอบสนอง และการวินิจฉัยที่แม่นยำ รวดเร็ว คุณภาพงานซ่อมสูง พร้อมการติดตามอย่างต่อเนื่องจนแล้วเสร็จ

บทความน่ารู้

เครื่องกำเนิดไฟฟ้าคืออะไร มีความสำคัญอย่างไรต่อธุรกิจ

เครื่องกำเนิดไฟฟ้าคืออะไร การเลือกเครื่องกำเนิดไฟฟ้าให้ดี สำคัญต่อธุรกิจของคุณอย่างไร และจะแน่ใจได้อย่างไรว่า เครื่องกำเนิดไฟฟ้าที่ติดตั้งอยู่นั้นจะเริ่มทำงานได้ทันทีและมีเสถียรภาพสูง

NEW! เครื่องยนต์ดีเซล Cummins ดีจริงไหม? เหมาะกับการใช้งานแบบใดบ้าง?

ทำความรู้จักเครื่องยนต์ดีเซล Cummins พร้อมบริการดีๆ จาก Cummins DKSH (Thailand) ผู้จัดจำหน่ายอย่างเป็นทางการเพียงผู้เดียวในประเทศไทย

NEW! อะไหล่เทียบใช้แทนอะไหล่แท้ Cummins ได้จริงหรือ?

เมื่อถึงเวลาที่ต้องเปลี่ยนอะไหล่ การทำความเข้าใจความแตกต่างระหว่าง อะไหล่แท้ Cummins และอะไหล่เทียบถือเป็นสิ่งสำคัญยิ่ง เพื่อป้องกันเครื่องยนต์ของคุณจากความเสียหายรุนแรงที่อาจเกิดขึ้นในอนาคตข้างหน้า

โครงการอ้างอิง

ลูกค้าในอุตสาหกรรมต่างๆ ให้ความไว้วางใจในผลิตภัณฑ์และบริการจากบริษัท คัมมิ่นส์ ดีเคเอสเอช (ประเทศไทย) จำกัด

ลงทะเบียนเครื่องยนต์/เครื่องกำเนิดไฟฟ้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

สอบถามข้อมูล

หรือคำแนะนำได้ที่นี่

หากคุณมีคำถาม? ต้องการสั่งซื้อ?

ทีมงานของเราพร้อมให้ความช่วยเหลือแก่คุณ